Equipment remote monitoring

Data is online in real time

Efficient fault alarm

Data report analysis

Equipment remote maintenance

Process flow visualization

Home

Product

Solution

About Us

Service Support

Link Us

Equipment remote monitoring

Data is online in real time

Efficient fault alarm

Data report analysis

Equipment remote maintenance

Process flow visualization

Switch

需求背景

解決方案

Internet of Everything

Intelligent Collection

Edge Computing

Cloud Application

方案拓撲

方案效益

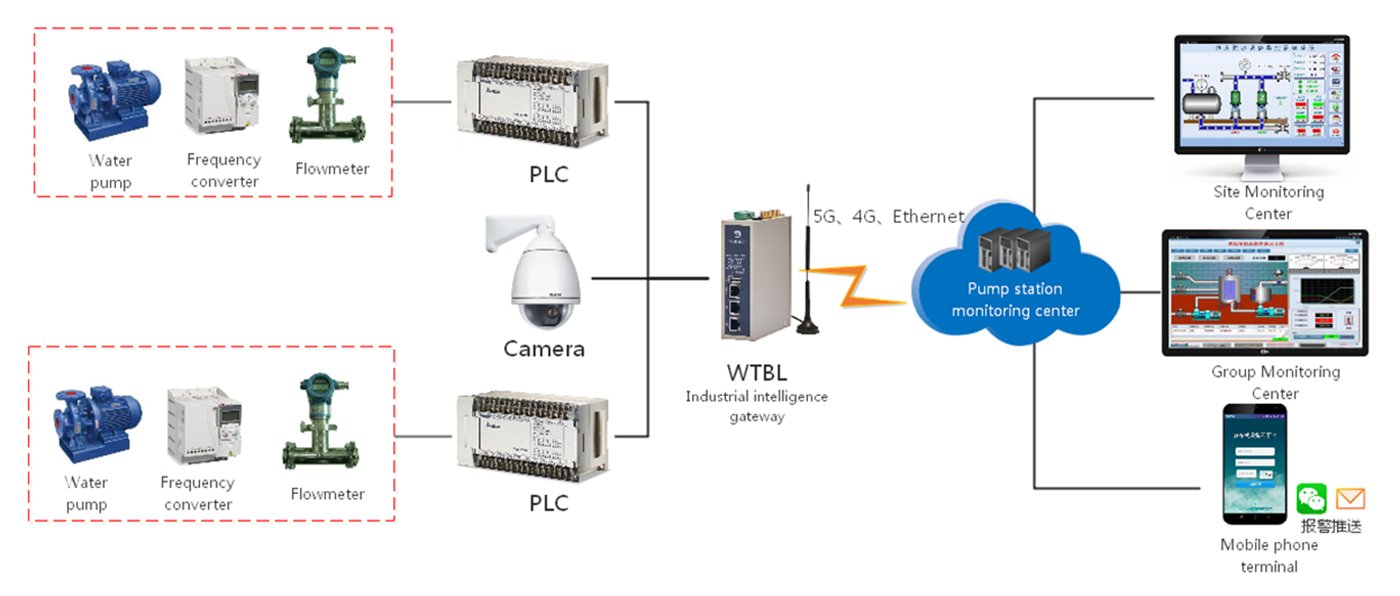

Realize remote monitoring of pumps, frequency converters, flow meters, PLCs and other equipment in pumping stations

The data is transmitted to the monitoring center of the pump station, and the status of the station can be remotely monitored at any time.

Automatic alarm for equipment failure, and alarm information is automatically pushed to the manager's mobile phone

Remote configuration, diagnosis and modification of the PLC program of the pump station are realized through the equipment express line to ensure the healthy operation and service life of the equipment.

Configuration monitoring to realize visual monitoring and management of process flow

Integrate and analyze data from multiple dimensions, provide big data support for pumping stations, and facilitate digital management and operation

應用案例

Realize the data visualization of factory

equipment network operation management and production line monitoring

and data interconnection of various information systems

Classic customers::

三一重工、京東方、富士康、寧德時代、愛仕達……

Realize data acquisition, remote control and maintenance of on-site equipment

Realize the monitoring of real-time data, historical data and alarm data

Realize operation management of field equipment and visual monitoring of production line data

Application industry projects:

rural sewage monitoring, urban sewage monitoring, secondary water supply monitoring……

Build a safe and reliable maintenance channel

Realize remote operation and maintenance of equipment distributed around the world

Reduce operating costs and improve service quality

Application industry:

water treatment equipment, construction machinery equipment, industrial lubrication equipment……

相關產品